The term dry-type transformer refers to an electrical transformer that relies on air or solid insulation instead of liquid for cooling and insulation. If your power-distribution system demands high safety, low maintenance, and environmental compliance — then a dry-type transformer may be the ideal choice. In this guide you’ll learn what a dry-type transformer is, how it works, its various types, advantages and limitations, and how to choose the right one for your application.

Article Content

What is a Dry-Type Transformer?

A dry-type transformer is a power transformer in which the core and windings are cooled by forced or natural air flow, and are insulated using solid/air insulation rather than liquid (such as oil). Because there’s no flammable fluid, these units are safer for indoor use, urban installations, and fire-sensitive environments.

How It Works

At its heart the dry-type transformer operates on the same electromagnetic principles of other transformers: the primary winding receives alternating current (AC), this creates a magnetic flux in the laminated core, which induces voltage in the secondary winding. The key difference is in how heat and insulation are managed — with solid and air cooling instead of immersion in oil.

Types of Dry-Type Transformers

Dry-type transformers are available in several construction and insulation styles. Understanding these helps you select the right type for your environment.

Cast Resin Transformer (CRT)

In a cast resin transformer the windings are fully encapsulated in epoxy resin. This seals out moisture, dust and corrosive gases, making CRTs (Cast Coil Dry-Type Transformers) ideal for indoor and harsh environments.

Vacuum Pressure Impregnated (VPI)

In VPI transformers the windings are impregnated with varnish under vacuum pressure and then baked. This improves insulation and mechanical strength compared with standard open-wound designs.

Vacuum Pressure Encapsulated (VPE)

VPE designs go further by encapsulating the windings in resin or other solid insulating compounds under vacuum pressure. They are excellent where high humidity or aggressive atmospheres exist.

Configuration by Cooling & Ventilation (Open-Wound Transformer)

Dry-type transformers can also be categorised by cooling method — AN (Air Natural), AF (Air Forced), AN/AF combinations — and by enclosure type (ventilated vs totally enclosed) depending on environmental demands.

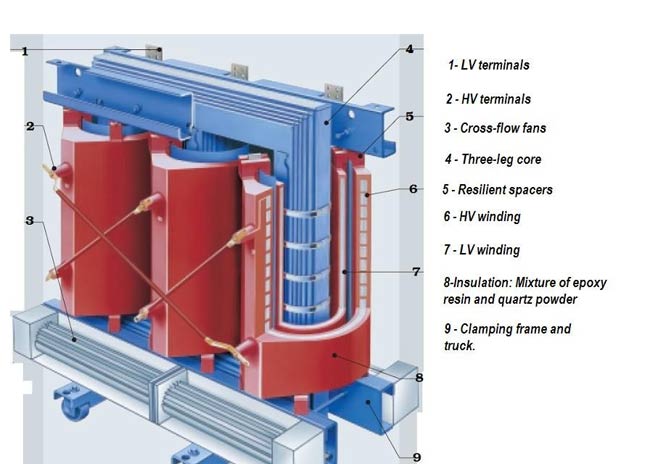

Composition of Dry Type Transformer

Dry-type transformers consist of several key components that ensure their efficient operation and durability:

- LV Terminals: Low voltage terminals connect the transformer to the load or distribution system.

- HV Terminals: High voltage terminals link the transformer to the power supply source.

- Cross-Flow Fans: These fans provide forced air cooling, enhancing heat dissipation in high-capacity transformers.

- Three-Leg Core: The magnetic core, usually made of laminated silicon steel, minimizes energy losses and provides a path for the magnetic flux.

- Resilient Spacers: These components ensure mechanical stability and proper spacing between the windings.

- HV Winding: High-voltage windings are insulated and designed to handle incoming high-voltage currents.

- LV Winding: Low voltage windings transfer reduced voltage currents to the connected load.

- Insulation: High-grade insulation materials protect the windings and prevent electrical faults.

- Clamping Frame and Truck: These provide structural support and enable easy transportation and installation of the transformer.

Each of these components plays a vital role in the overall functionality and safety of the transformer.

Cooling Methods & Insulation Systems

Proper cooling is vital to transformer longevity. In dry-type designs air is the cooling medium — either natural circulation or forced via fans/blowers. The insulation system (varnish, resin, epoxy) is chosen based on environmental severity. According to industry guidance, these choices directly impact rated life and service reliability.

Key Specifications & Standards

When selecting or specifying a dry-type transformer, you must consider: rated power (kVA), primary/secondary voltage, insulation class (e.g., F or H), cooling method, temperature rise, altitude, short-circuit withstand, sound level, enclosure IP/NEMA rating. Standards that apply include: IEC 60076‑11 (for dry power transformers), IEEE C57.12.01, ANSI/NEMA ST 20.

Advantages & Disadvantages

Advantages

- Very low fire risk — no flammable oil.

- Environmentally friendly — no risk of oil leakage.

- Low maintenance — no oil checks, no filtration.

- Can be installed indoors and in public spaces.

- Good reliability and lifespan (25-30 years typical).

Disadvantages

- Higher initial cost than comparable oil-filled units.

- Cooling is less efficient than liquid-cooled, limiting top end power ratings.

- Slightly higher temperature rise, may need more ventilation.

- Noise and air-flow may be a factor in particular environments.

Dry-Type vs Oil-Filled Transformer

Here’s a comparison table:

| Feature | Dry-Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Cooling medium | Air / solid insulation | Mineral or silicone oil |

| Fire risk | Very low | Moderate-to-high |

| Maintenance | Low | Higher (oil checks, filters) |

| Environmental impact | No oil leakage risk | Oil contamination possible |

| Installation location | Indoor or public areas | Typically outdoor or enclosed |

| Cost | Higher upfront | Lower upfront |

| Typical power range | Up to perhaps ~30 MVA* | Up to 100s of MVA |

Protection Mechanisms for Dry-Type Transformer

Given their critical role, ensuring the protection of dry-type transformers is paramount. Proper protection safeguards the equipment from overloads, short circuits, and other electrical anomalies. Key protection mechanisms include:

Overcurrent Protection

Overcurrent protection is essential to prevent overheating due to excessive current. Relays are configured to trip circuit breakers when fault currents exceed safe operating limits. Time-current settings ensure coordination across the power system.

Differential Protection

Differential protection monitors the current entering and leaving the transformer. Any imbalance indicates a fault within the transformer, triggering immediate isolation to prevent damage.

Thermal Protection

Thermal sensors embedded within the windings monitor temperature. If the transformer exceeds its safe operating temperature, alarms or automated trips are activated.

Restricted Earth Fault (REF) Protection

This protection is critical for detecting low-magnitude ground faults within the transformer windings. REF systems ensure swift fault clearance, reducing potential damage.

Voltage Protection

Overvoltage and undervoltage relays protect the transformer against fluctuations that could lead to insulation breakdown or winding damage.

Applications & Use-Cases

Dry-type transformers are widely used in:

- Commercial buildings (malls, offices, hospitals) where fire safety is critical.

- Industrial plants where maintenance access is limited.

- Renewable energy systems (solar farms, wind power) where environmental sealing is essential.

- Urban substations, rail/metro systems.

- High-end residential complexes or data-centres where oil-filled units may pose a risk.

Installation & Maintenance Considerations

- Ensure adequate ventilation and clearances around the unit to allow airflow.

- Keep ventilation ducts and filters clean.

- For forced-air types check fan operation and redundancy.

- Monitor temperature rise, insulation resistance periodically.

- Avoid installing in locations with high dust, moisture, corrosive gases — unless you selected the correct encapsulation type.

- Ensure proper grounding and protective devices.

- Perform infrared scans and check for loose connections.

Dry-Type Transformer Efficiency & Losses

The efficiency of a dry-type transformer typically ranges from 97% to 99%, depending on load conditions and design. Core losses (no-load losses) occur due to magnetizing current, while copper losses (load losses) depend on winding resistance. Modern dry-type transformers use high-grade silicon steel and low-loss conductors to minimize energy waste and comply with IEC 60076-20 efficiency standards.

Frequently Asked Questions (FAQ)

What is the difference between a cast resin dry-type transformer and a VPI type?

Cast resin units have windings fully encapsulated in epoxy, making them highly resistant to moisture/corrosion; VPI units use varnish under vacuum pressure, offering good strength but less encapsulation than cast resin.

When should you choose a dry-type transformer instead of oil-filled?

Choose dry-type when fire safety, low maintenance, indoor or public installation, and environmental protection are key considerations. Oil-filled might be chosen where very high power (MVA) is needed, or cost is critical and outdoor space is available.

Can dry-type transformers handle harmonic loads?

Yes — there are special dry-type models rated for harmonic loads (K-factor, harmonic-mitigating designs) to handle non-sinusoidal currents typical of modern drives and electronics.

What standards govern dry-type transformers?

Key standards include IEC 60076-11, IEEE C57.12.01, ANSI/NEMA ST 20 among others.

Conclusion

In summary, the dry-type transformer is a safe, efficient and increasingly popular choice for modern electrical installations — particularly where fire risk, environmental compliance and indoor installations matter. While the upfront cost may be higher and cooling less efficient than oil-filled units, the long-term benefits in maintenance, safety and flexibility make it a smart investment for many applications.

If you’re specifying or purchasing a dry-type transformer, apply the selection criteria above, compare product options, and consult trusted manufacturers. With the right choice, you’ll ensure reliability, efficiency and safety for years to come.