In the dynamic world of industrial and power automation, two pivotal technologies—Programmable Logic Controllers (PLCs) and Remote Terminal Units (RTUs)—stand out for their roles in controlling and monitoring processes. While they share similarities as industrial computing devices with CPUs, I/O modules, and network interfaces, their differences in design, functionality, and application make them suited to distinct scenarios.

This in-depth exploration draws from technical sources to provide a balanced view, highlighting how these devices evolved, their architectural nuances, and practical considerations for implementation. Whether you’re an engineer optimizing a factory floor or a utility manager overseeing vast networks, understanding these distinctions can guide better system choices.

Article Content

What is a PLC?

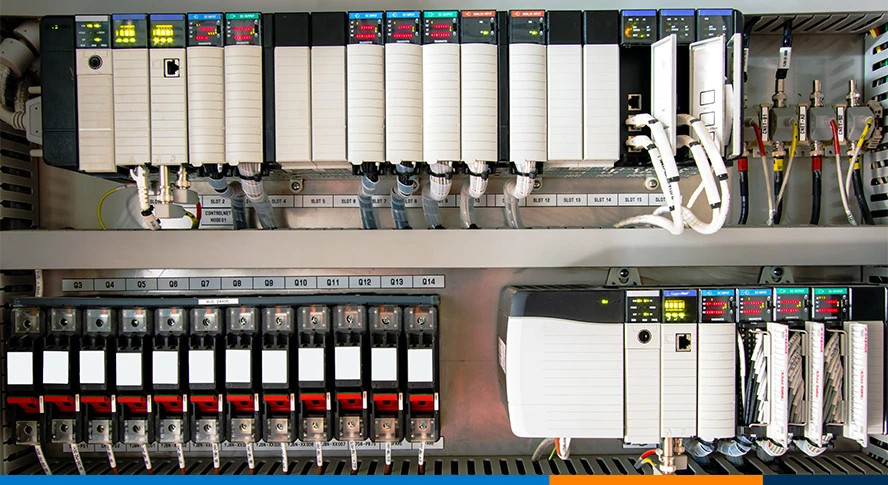

A Programmable Logic Controller (PLC) is a specialized industrial computer used to automate processes by reading inputs from sensors, executing programmed logic, and controlling outputs like motors or valves. Developed in the late 1960s to replace relay systems, PLCs are compact and versatile, ideal for factories where space and precision matter.

What is an RTU?

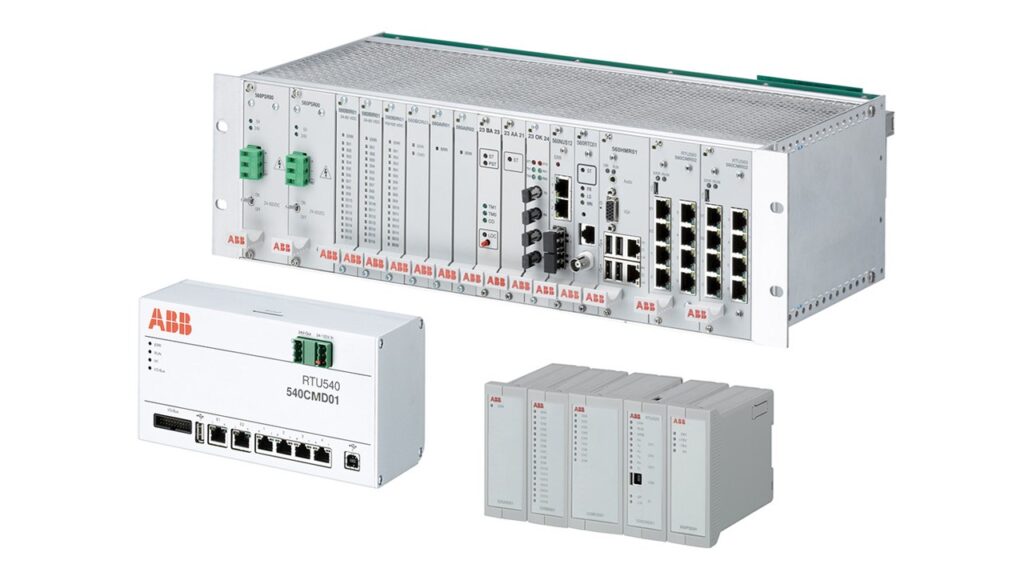

A Remote Terminal Unit (RTU) is a microprocessor-based device that interfaces with remote field equipment, collecting data and issuing commands in SCADA systems. Originating in the 1950s for telecommunications, RTUs are built for durability and long-distance communication, often in challenging outdoor environments.

Architectural and Design Distinctions

At a foundational level, both PLCs and RTUs process inputs, execute commands, and manage outputs, but their architectures reflect different priorities. A PLC typically includes a CPU for logic execution, modular I/O for sensor integration, and basic communication ports, making it compact for space-limited setups. RTUs, often viewed as self-contained units, add integrated power supplies, battery backups, and enhanced modularity, enabling operation in isolated areas with minimal infrastructure.

One key divergence is environmental resilience. RTUs are engineered for extreme conditions, such as temperatures from -40°C to +70°C, high humidity, and dust-prone sites, often with IP65-rated enclosures. This ruggedness contributes to their larger size compared to PLCs, which are designed for milder indoor environments (-20°C to +60°C) and prioritize compactness over endurance.

In terms of processing, high-end RTUs feature powerful 32-bit CPUs clocked at 200 MHz, supporting rapid data handling and features like 1-ms timestamping for Sequence of Events logging. PLCs, while capable, often use less intensive processors suited for cyclic control loops rather than high-volume data aggregation.

Communication capabilities further set them apart. RTUs support a wide array of protocols (e.g., DNP3, Modbus, IEC 60870) and mediums like radio, cellular, or satellite, with features such as report-by-exception to minimize bandwidth use in remote links. PLCs provide solid but more limited networking, frequently requiring add-ons for advanced multi-protocol or peer-to-peer interactions. Programmability also varies: PLCs offer rich languages including structured text and function blocks for complex algorithms, whereas RTUs lean toward configuration-based interfaces, simplifying setup for monitoring but limiting intricate logic.

I/O handling is another area of contrast. RTUs boast higher-density I/O (e.g., 16-bit analog inputs and fast counters) and local processing to filter data before transmission, reducing network load. PLCs are expandable but may need more modules for similar capacity in large systems. Security features in modern RTUs include built-in encryption and firewalls, while PLCs often rely on external enhancements.

Performance and Operational Capabilities

Performance metrics underscore their optimizations. RTUs achieve ultra-fast cycle times (around 1 ms) for real-time monitoring, excelling in data logging and autonomous operation during communication outages. PLCs focus on deterministic execution for control tasks, with cycle times varying based on program complexity but optimized for reliability in loops.

In terms of scalability, RTUs’ modular design facilitates easy expansion and remote firmware updates, lowering maintenance costs in dispersed networks. PLCs shine in integrated environments, supporting extensive add-ons for functionality growth. Cost-wise, PLCs can be more affordable for basic setups, but RTUs’ durability often justifies higher initial investments in demanding applications, with total ownership costs favoring RTUs for remote sites.

Applications Across Industries

PLCs dominate in localized, high-precision settings like automotive assembly, food processing, and packaging, where their programmability enables seamless integration into production workflows. RTUs are indispensable in remote and utility sectors, such as oil pipelines, water treatment, power grids, and agriculture, where they handle telemetry over vast areas with minimal intervention. In SCADA frameworks, RTUs serve as edge nodes for data relay, complementing PLCs that manage core logic.

Emerging trends include hybrid devices that combine PLC flexibility with RTU resilience, addressing overlapping needs in smart grids or IoT-enabled factories.

In summary, while PLCs and RTUs overlap in core functions, their specialized designs make them complementary tools in automation ecosystems. By evaluating specific needs—such as location, scalability, and environmental demands—professionals can leverage these technologies for optimal performance.