The Chopped Wave Lightning Impulse Test is one of the most severe dielectric tests performed on high-voltage power transformers. While a normal lightning impulse test checks how a transformer handles a standard 1.2/50 μs surge, the chopped wave represents a much sharper, more dangerous type of overvoltage that can happen in real power systems.

IEC 60076-3 requires the Chopped Wave Lightning Impulse Test for transformer windings rated above Um = 170 kV, because at these voltage levels the insulation is more sensitive to steep, fast-rising overvoltages. The LIC test helps ensure the transformer can survive these extreme conditions throughout its lifetime.

Table of Contents

What Is a Chopped Wave Lightning Impulse Test?

A Chopped Wave Lightning Impulse begins like a normal lightning impulse but is intentionally interrupted after only a few microseconds. This interruption is created using a small air gap (called a chopping gap) placed close to the line terminal of the transformer.

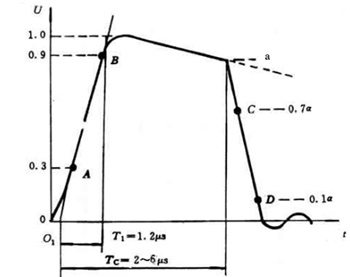

Once the gap flashes over—usually between 2 and 6 microseconds after the start of the wave—the voltage collapses suddenly. This creates a very steep front and a sharp high-frequency oscillation.

In simple words:

The chopped wave is a lightning impulse that breaks early, creating the most severe type of fast-front stress a transformer may ever experience.

IEC uses this test because real lightning surges can be suddenly interrupted by a flashover on a bushing, disconnect switch, or insulator near the transformer.

Why the Chopped Wave Lightning Impulse Test Is Important

The main purpose of the LIC test is to check the line-end insulation, which is the part of the winding that first receives the surge. This area faces the highest electrical stress because steep-front impulses force most of the voltage onto the first few turns.

The Chopped Wave Lightning Impulse Test verifies that the transformer can withstand:

- Very fast voltage rise

- Extremely high dV/dt (rate of rise of voltage)

- Local stress on the first turns of the winding

- High-frequency components

- Sudden voltage redistribution after chopping

IEC 60076-3 explain that insulation withstand strength decreases as the impulse becomes faster. Because of this, chopped waves are more severe than standard lightning impulses, and they must be tested separately on high-voltage transformers.

How the Test Voltage Is Selected

IEC 60076-3 provides a voltage table that links each system voltage (Um) with its required LIC test level. These test levels are typically higher than the standard lightning impulse levels to reflect the added severity of the chopped wave.

For example:

- Um = 170 kV → LIC = 715 kV

- Um = 245 kV → LIC can be 935 kV or 1 045 kV

- Um = 420 kV → LIC up to 1 430 kV

The rule is simple:

The test voltage must not be lower than the IEC minimum value.

How the Chopped Wave Lightning Impulse Test Is Performed

The Chopped Wave Lightning Impulse Test (LIC) is performed in almost the same setup as the full-wave lightning impulse test, but with one important addition: a chopping gap is used to force the impulse to “break” early. This creates a much steeper front, which places severe electrical stress on the line-end turns of the winding. The procedure is clearly defined in IEC 60076-3.

1. Preparing the Waveform

According to IEC 60076-3, the chopped wave must look like a normal full lightning impulse at the beginning, but the voltage must be interrupted between 3 μs and 6 μs after the start of the front. This interval is called the chopping time.

A slightly earlier chopping time—between 2 μs and 3 μs—may be accepted if both parties agree, as long as the wave reaches its peak before it is chopped.

IEC also requires:

- The first zero crossing after the chop should occur as soon as possible, producing a sharp collapse of the voltage.

- No extra impedance should be added to the chopping circuit unless needed to limit overswing to below 30%.

Only the chopping equipment is added; all other impulse generator settings normally remain the same.

2. Chopped Wave Test Sequence (Transformers Without Non-Linear Elements)

IEC 60076-3 states that the LIC test is performed within the same sequence as the full-wave impulse test. The standard procedure is:

- One reduced full-wave impulse at 50–70% of the LI test voltage

- This verifies polarity and checks the measuring setup.

- One full-wave impulse at 100% of the LI test voltage

- Confirms waveform and transformer behavior.

- Two chopped-wave impulses at the LIC test voltage

- These are the main LIC impulses and must chop at the correct time (2–6 μs).

- All chopped waves should ideally use the same chopping time.

- Two more full-wave impulses at 100% of LI voltage

- Used for comparison to ensure no deterioration occurred during the chopped impulses.

If a flashover occurs outside the winding (for example on a bushing), that specific shot is ignored and repeated.

3. Criteria for Passing the Test

The transformer passes the LIC test if the recorded voltage and current waveforms show:

- No internal flashover,

- No collapse or distortion up to the chopping time, and

- No significant difference between reference impulses and full-voltage/chopped impulses (up to the chop point).

Differences after the chopping instant are acceptable because small variations in gap timing are normal.

4. Transformers With Non-Linear Elements

If the transformer contains internal surge arresters, spark gaps, or other non-linear components, IEC requires a modified sequence. These components may begin conducting above a certain threshold, so the test must include impulses below and above that activation level.

The sequence becomes longer:

- Three reduced full impulses (50–90%),

- One full-wave impulse,

- Two chopped-wave impulses,

- Two more full-wave impulses,

- Then three comparison impulses matching the earlier levels.

This ensures that any waveform differences are due to normal behavior of the non-linear elements, not insulation failure.

5. General Notes From the Standard

- A triggered chopping gap with adjustable timing is recommended, but a rod-rod gap is allowed.

- The peak value of the chopped impulse must match the LIC test level defined in Table 2.

- Additional impulses at lower levels may be used for tuning but do not need to appear in the test report.

Why the Chopped Wave Lightning Impulse Test Matters

The LIC test is essential for high-voltage and extra-high-voltage transformers because it confirms that the transformer can survive:

- Very steep lightning surges

- Flashovers in nearby equipment

- High-frequency voltage spikes

- Local insulation stress at the line terminal

Transformers that pass the Chopped Wave Lightning Impulse Test are far less likely to experience insulation failure in service, especially in environments with frequent lightning or complex switching operations.

Conclusion

The Chopped Wave Lightning Impulse Test is one of the most important and severe dielectric tests defined by IEC 60076-3. It ensures that transformers with higher voltage ratings can handle the steepest and most dangerous lightning surges they may face in real electrical networks. By applying a controlled early flashover, measuring the waveform, and checking for any insulation damage, manufacturers and utilities can confirm that the transformer’s line-end insulation is strong, reliable, and ready for decades of safe operation.